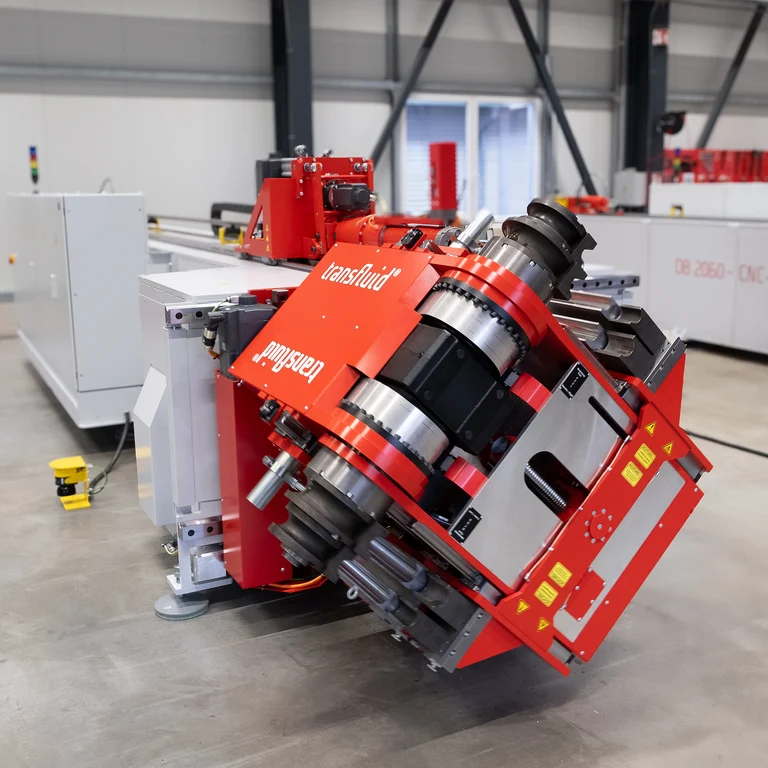

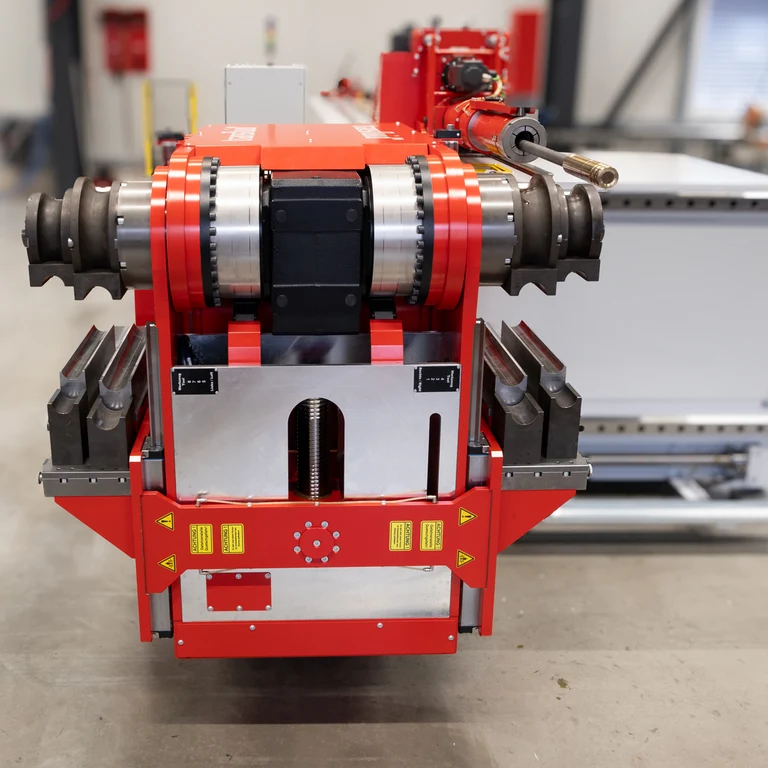

t bend - fully automated CNC tube bending machines:

Satisfy even the toughest requirements

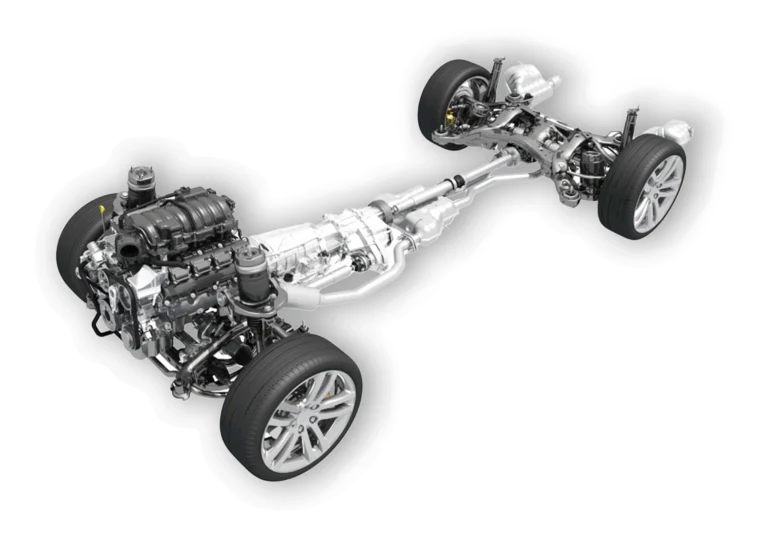

We add movement to your projects: transfluid offers client-specific solutions in the automotive industry, together with comprehensive expertise for all areas in this sector. Completely new challenges lie ahead with future technologies, such as fuel cells in electromobility.

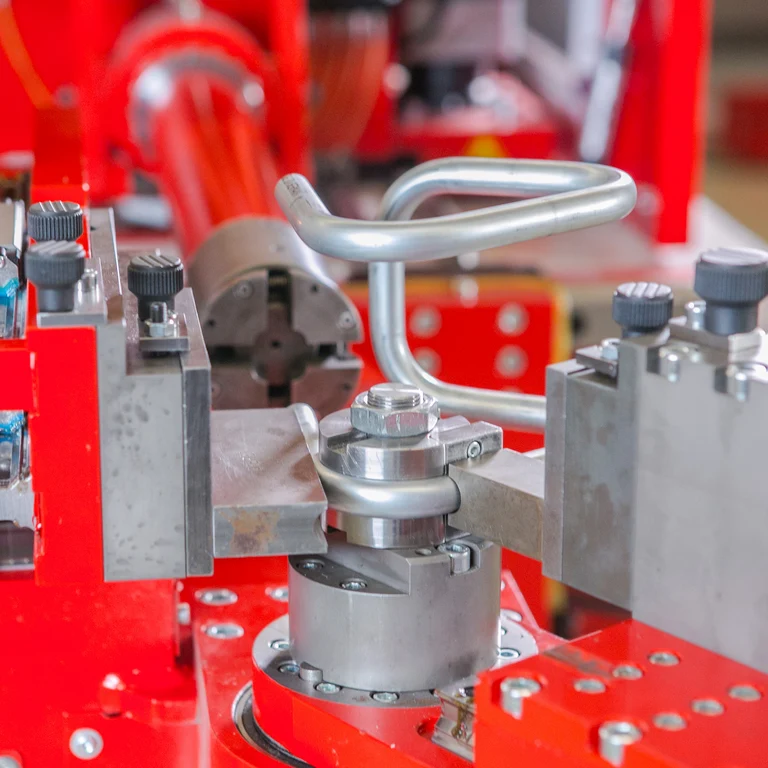

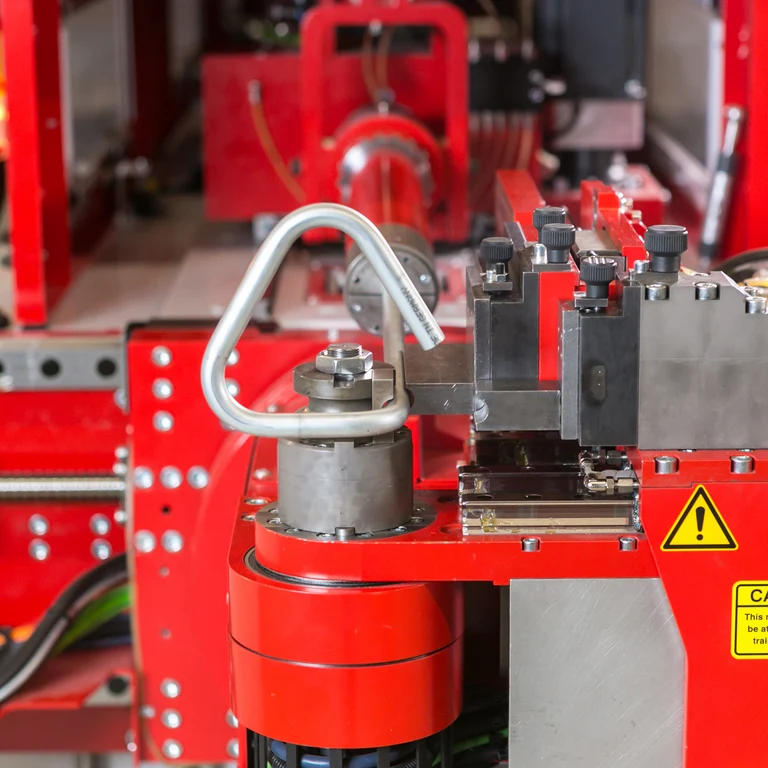

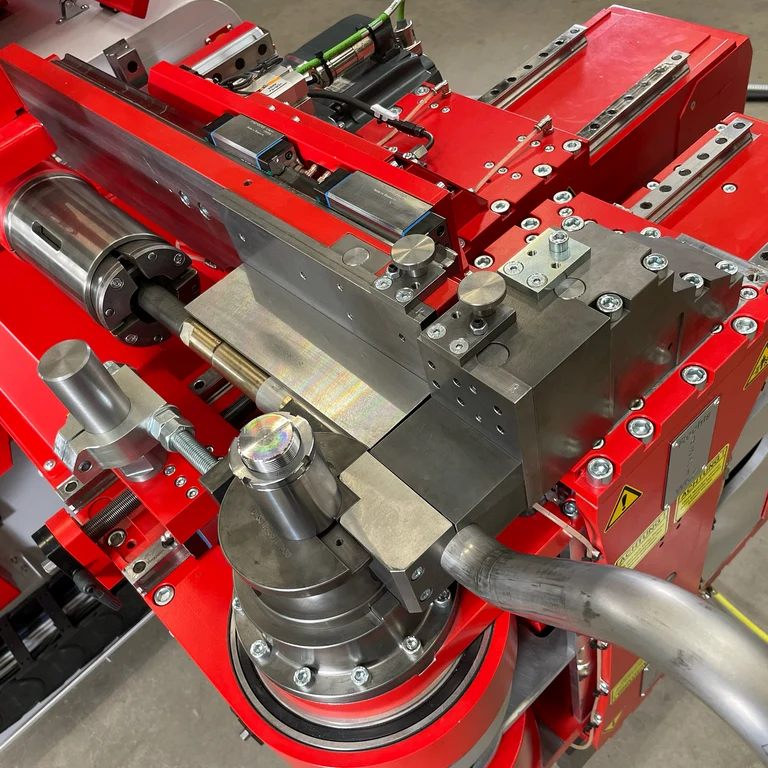

The right machine for your task

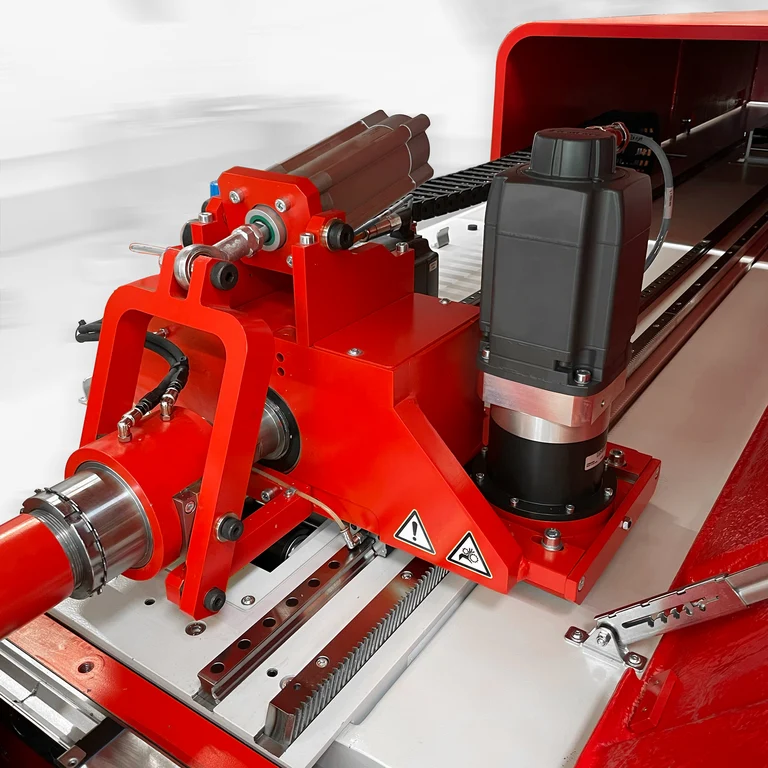

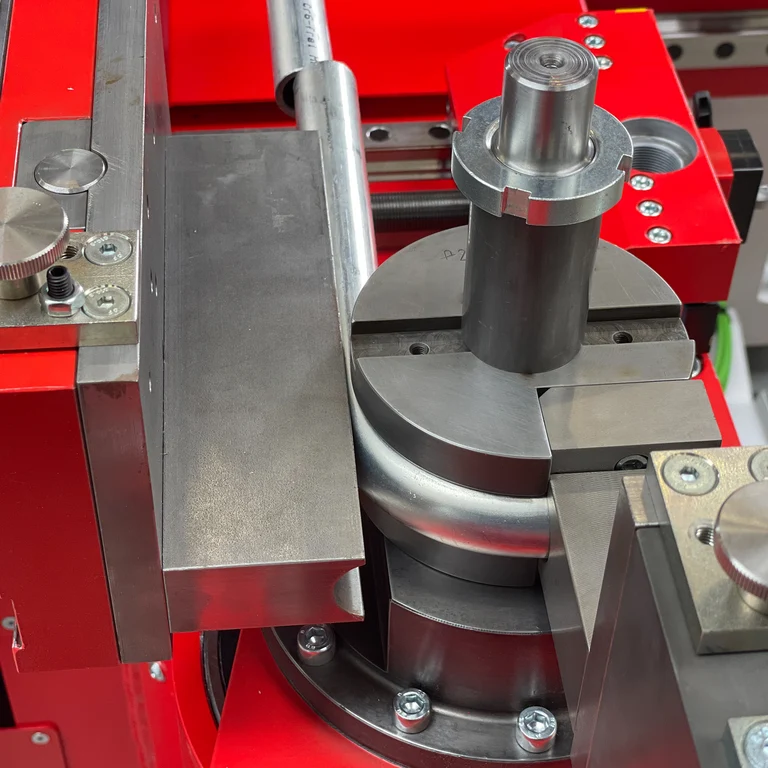

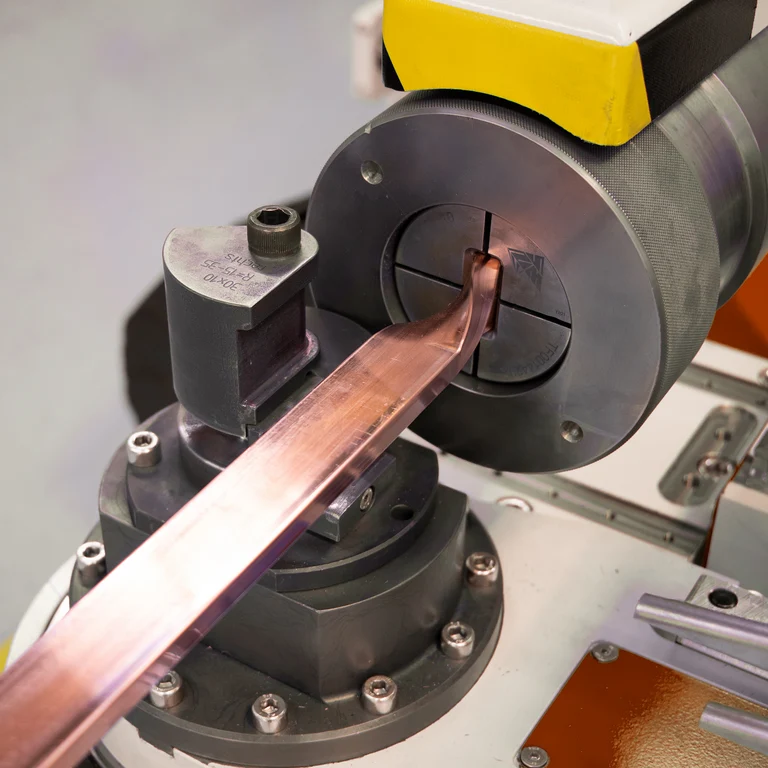

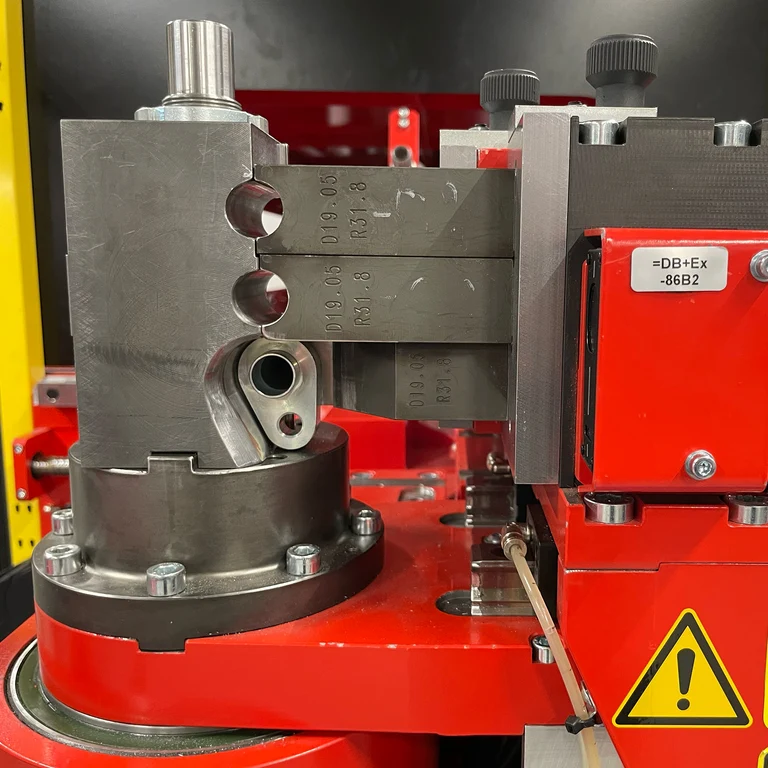

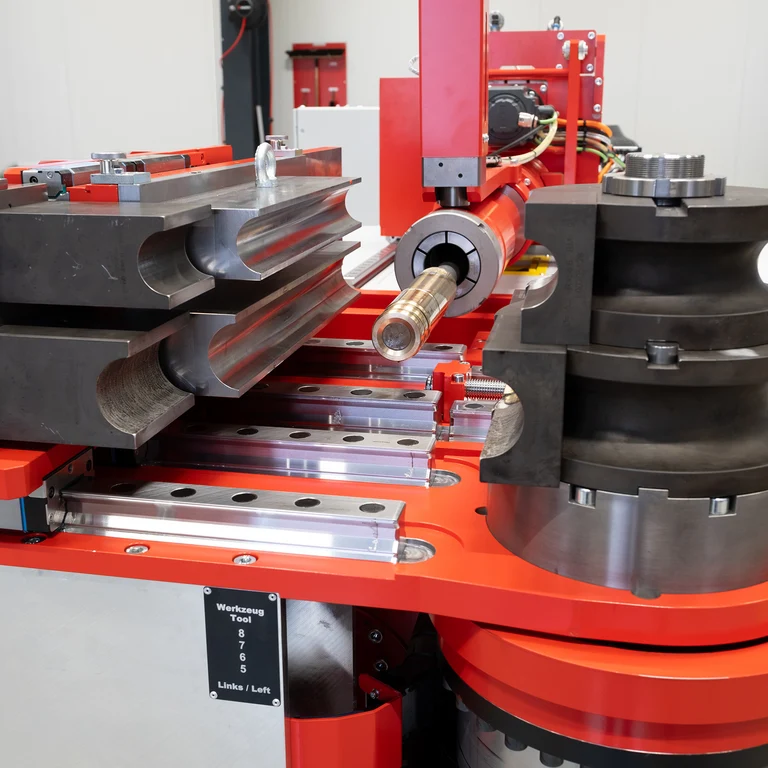

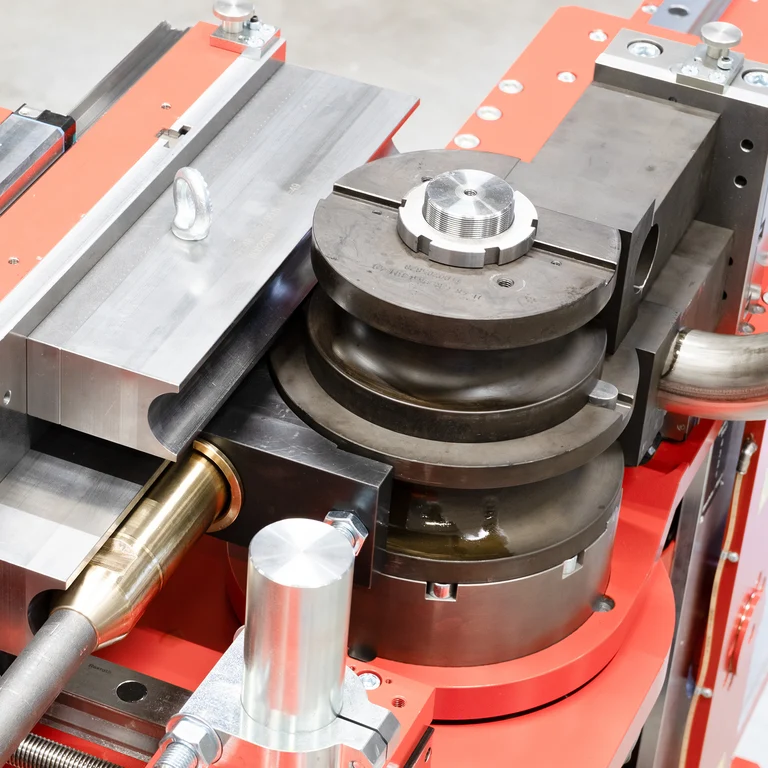

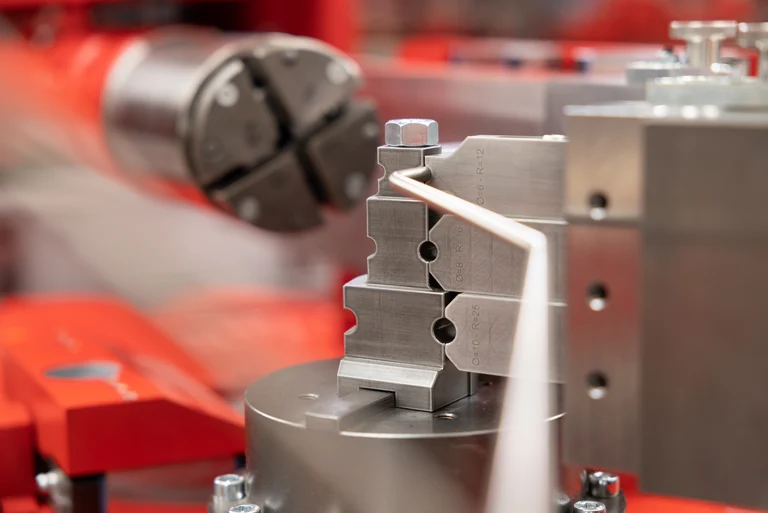

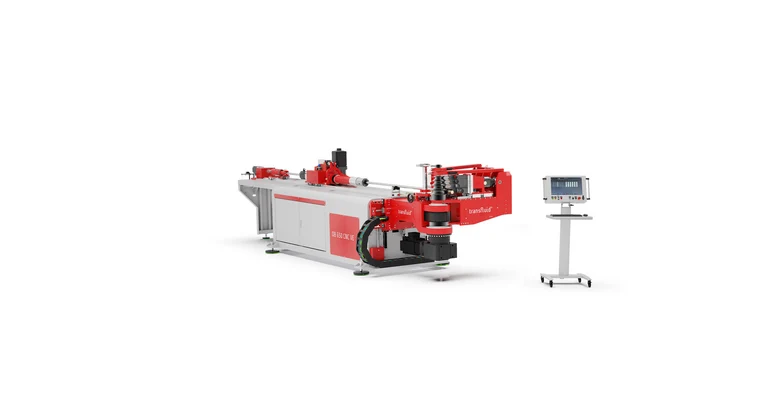

MANDREL BENDING MACHINES Right/Left Bending with CNC-Control

| Range | 3/16" - 7/8" |

| Max. capacity | 7/8" x .72" (mild steel) 7/8" x .049" (stainless steel) |

| Max. Radii | 2.6" |

| Usable length | 6.5 ft (standard) 10 ft 15 ft 20 ft (special) |

| Speed of bending axis | 300 °/sec. |

| Range | 3/16" - 1 1/8" |

| Max. capacity | 1 1/8" x .72" (mild steel) 1 1/8" x .049" (stainless steel) |

| Max. Radii | 3.5" |

| Usable length | 6.5 ft (standard) 10 ft 15 ft 20 ft (special) |

| Speed of bending axis | 275 °/sec. |

| Range | 1/4" - 1 5/8" |

| Max. capacity | 1 5/8" x .120" (mild steel) 1 5/8" x .120" (stainless steel) |

| Max. Radii | 6.6" |

| Usable length | 6.5 ft 10 ft (standard) 15 ftmm 20 ft (special) |

| Speed of bending axis | 180 °/sec. |

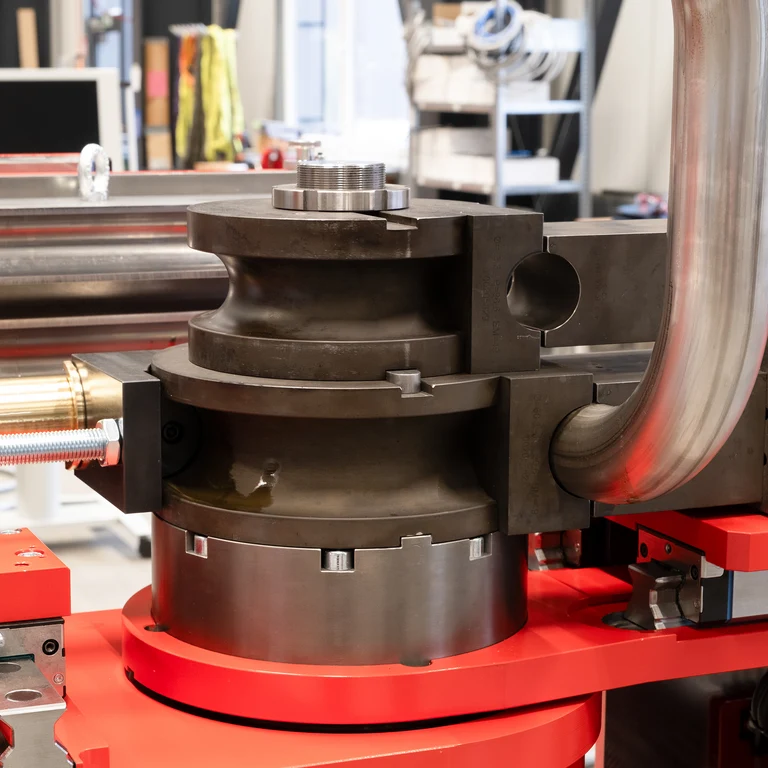

| Range | 1/4" - 2 3/4" |

| Max. capacity | 2 3/4" x .154" (mild steel) 2 3/8" x .095" (stainless steel) |

| Max. Radii | 7.1" |

| Usable length | 10 ft (standard), 15 ft, 20 ft (special) |

| Speed of bending axis | 100 °/sec. |

Tube bending machines and excellent service

Gives service technicians remote access to machine controls.

The excellent 24-hour after-sales service from transfluid® also guarantees particular sustainability of our solutions.

Flexible, fast and comprehensive spare parts supply through spare parts warehouse in the USA.

t project - Software: virtual support for HIGHER efficiency

Fewer steps to the finished workpiece: With t project you can see all the variables of the bending process before starting the production. Even complex bending geometries can be planned and executed in a material-adapted and collision-free manner.

The virtual bending simulation determines exact bending times and cutting lengths and checks tube geometries for feasibility in advance. Tube data and bending results are documented with accuracy and they can then be replicated 100% . The common interfaces are available for the import and export of data and connection to PDA or ERP over the network.

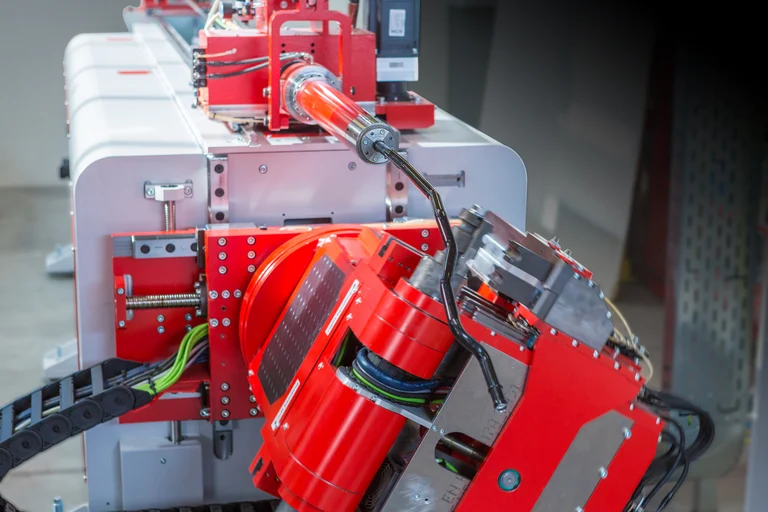

t motion - Automation

For an ideal production workflow

With t motion we plan and execute manufacturing islands or cells for your tube processing with optimized material flow. We design a layout to match your requirements and integrate all the required processing and handling options. With our 30 years of experience with automation we can offer you a solution for tubes at the highest level.